|

| Callsign

~ Tradewind Cargo (download here) |

|

|

PJ-GBF

TEXTURES

ONLY - You need to have

TDM

ATR72 PJ-GBH

already installed

FDE

Update

|

Aerospatiale

ATR72-500 ~ Francisco Sánchez-Castañer

The

ATR-72 is a stretched development of the popular ATR-42

and was launched in January 1986.

Significant

differences between the ATR-72 and the smaller and older

ATR-42 include a 4.50m (14ft 9in) fuselage stretch and

reworked wings. The ATR-72's wings are new outboard of

the engine nacelles and with 30% of it made up of composite

materials, comprising composite spars and skin panels

and a carbon fibre wing box.

Aside

from the baseline ATR-72-200, two developments have been

offered, the ATR-72-210, and the ATR-72-500 (previously

ATR-72-210A). The ATR-72-210 is optimised for operations

in hot and high conditions. It has more powerful PW-127

engines for better takeoff performance.

The

ATR-72-500 (renamed from ATR-72-210A on May 18, 1998)

further improved hot and high model was certificated in

early 1997. It features PW-127Fs driving six blade composite

Hamilton Sundstrand propellers.

|

|

|

Other Suggested Files:

WARNING !

This archive comes with an aircraft specific version of FSUIPC.

If you have a registered copy of FSUIP back it up first and reinstall

it after you've installed this aircraft. I included it because the

panel will not work without FSUIPC.

Alternatively install it to a dummy location and deselect that

file when moving files to FS9

|

Repaint by JF

Textures ONLY

|

|

PJ-CFC

'Starlight Trader'

FS9

ONLY

|

Airbus

A300-600F ~ HNAC

The

A300-600 development of the earlier A300B4 incorporated

a number of significant improvements and refinements,

foremost being a two crew flightdeck and increased range.

Apart from the two crew EFIS cockpit, with digital avionics

based on that developed for the A310, changes included

the A310's tail empennage which increased freight and

passenger payloads, small winglets (an option from 1989,

standard from 1991), simplified systems, greater use of

composites, Fowler flaps and increased camber on the wings,

new brakes and APU, and improved payload/range through

an extensive drag reducing airframe clean up and new engines.

First flight for the A300-600 was on July 8 1983, the

first airline delivery was in March 1984.

The A300-600 was further developed into the longer range

A300-600R, its extended range courtesy of a fuel trim

tank in the tailplane and higher maximum takeoff weights.

First flight was on December 9 1987, first delivery was

April 20 1988 (to American Airlines).

Convertible freight/passenger versions of all variants

of the A300 have been offered, as has the all freight

A300F4-600. The first new build pure freighter A300, one

of 36 ordered for Federal Express, flew in December 1993.

UPS is another major A300-600F customer, following its

September 1998 order for 30. Airbus also offers conversion

packages of existing passenger A300s into freighters with

a left side forward freight door and strengthened floor.

|

|

|

Other Suggested Files:

|

Repaint by Meindert

Wijnberg

|

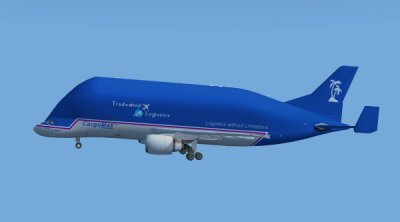

PJ-BGA Tradewind Logistics

and

N306TA Tradewind Alaska Cargo

FSX

ONLY

|

Airbus

A300-600ST Beluga ~ Tom Ruth

The A300-600ST Super Transporter was designed to replace Airbus Industrie's Super Guppy transports, used by the consortium to ferry oversize components such as wings and fuselage sections between Airbus' partners' plants throughout western Europe.

Development of the A300-600ST, nicknamed Beluga and also Super Flipper, began in August 1991. The A300-600ST's tight development program - for what in many ways is effectively a new aircraft - saw the transport rolled out in June 1994, with first flight on September 13 that year. The A300-600ST then entered a 400 hour flight test program which culminated in mid 1995, with certification awarded that September and with delivery and entry into service with Airbus in January 1996. All of the first four on order had been delivered by mid 1998 (allowing the Super Guppy's retirement in October 1997). The fifth Super Transporter is scheduled to be delivered in 2001.

The A300-600ST is based on the A300-600 airliner, with which it shares the wing, lower fuselage, main undercarriage and cockpit. The main differences are obvious - a bulged main deck, new forward lower fuselage, new enlarged tail with winglets and an upwards hinging main cargo door. A design study of a similarly configured A340, the A340ST Mega Transporter, to carry A3XX components is underway.

Program management of the A300-600ST is the responsibility of the Special Aircraft Transport Company, or SATIC, an economic interest grouping formed on a 50/50 basis by Aerospatiale and DASA operating on behalf of Airbus Industrie. While much of the work on the aircraft is performed by the Airbus partners, other European companies are also involved in the program.

|

|

Other Suggested Files:

|

Repaint by JF

|

PJ-CCB 'Caracas Trader'

FSX

ONLY

UPDATED - PW Freighter version 21 Dec 2009

|

Airbus

A330-200F ~ Tom Ruth

The

A330-200 is the newest member of Airbus' widebody twinjet family and is a long range, shortened development of the standard A330, developed in part as a replacement for the A300-600R and a competitor to the 767-300ER.

Airbus launched development of the A330-200 in November 1995, followed by the first customer order, for 13 from ILFC, placed in February 1996. First flight was on August 13 1997, with certification and first customer deliveries,to ILFC/Canada 3000, in April 1998.

The A330-200 is based on the A330-300 and shares near identical systems, airframe, flightdeck and wings, the only major difference being the fuselage length. Compared with the 300 the A330-200 is 10 frames shorter, and so has an overall length of 59.00m (193ft 7in), compared with 63.70m (209ft 0in) for the standard length aircraft. This allows the A330-200 to seat 256 passengers in a three class configuration, or alternatively 293 in two classes.

Because of its decreased length the A330-200 features enlarged horizontal and vertical tail surfaces (to compensate for the loss of moment arm with the shorter fuselage). Another important change is the addition of a centre fuel tank, which increases the A330-200's fuel capacity over the 300's, and results in the 200's 11,850km (6400nm) range.

Like the A330, engine options are the GE CF6-80, Pratt & Whitney 4000 series and the RollsRoyce Trent 700.

The A330-200 has sold quite strongly since its launch. Among the initial A330-200 customers are, apart from ILFC, Canada 3000, Korean Air, Austrian, Air Transat, Emirates, Swissair, Sabena, Monarch, Asiana, TAM, and Air Lanka.

|

|

Other Suggested Files:

|

Repaint by JF

|

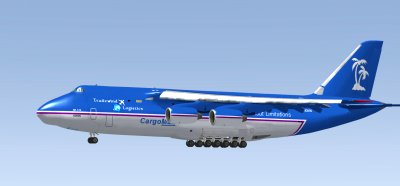

|

RA

82005 (FS9 version)

Updated FS9

aircraft.cfg

file (courtesy of Karl Hajek)

FSX version

RA

82050 CargoMax (with updated textures) NEW

FSX ONLY

|

Antonov

An-124-100 ~ Thomas Ruth

For

a time the massive An-124 held the mantle of the world's

largest aircraft before the arrival of the An-225, a stretched

six engine derivative. It is commonly used for oversize

freight charters.

Developed primarily as a strategic military freighter

(in which role it can carry missile units and main battle

tanks), the first prototype An-124 flew on December 26

1982. A second prototype, named Ruslan (after a Russian

folk hero), made the type's first western public appearance

at the Paris Airshow in June 1985, preceding the type's

first commercial operations in January 1986. Since that

time the An-124 has set a wide range of payload records,

a recent achievement being the heaviest single load ever

transported by air - a 124 tonne (273,400lb) powerplant

generator and its associated weight spreading cradle,

a total payload weight of 132.4 tonnes (291,940lb), set

in late 1993.

Notable features include nose and tail cargo doors, 24

wheel undercarriage allowing operations from semi prepared

strips, the ability to kneel to allow easier front loading,

and flybywire control system.

The two major An-124 variants are the basic An-124 and

similar Russian civil certificated An-124100. Various

upgrades have been proposed, including the western avionics

equipped An-124100M built in prototype form but not flown,

the three crew EFIS flighdeck equipped An-124102 and the

An-124FFF firebomber.

|

|

|

Other ESSENTIAL Files:

|

Repaint by JF

|

RA

82060 CargoMax (with updated textures)

FSX ONLY

|

Antonov

An-225 ~ Thomas Ruth

Antonov An-225 "Mriya" is the world's largest aircraft. When it was built, it surpassed any airliner built before by 50%. It was designed for the transportation of the Russian Space Shuttle "Buran" by the Antonov Design Bureau (HQ in Kiev, Ukraine), which already had built good and large cargo aircraft such as the Antonov An-124 "Ruslan". The basic configuration of the An-225 is the same as the An-124, except the An-225 is longer, has no rear ramp/door assembly, and incorporates a 32-wheel landing gear system (two nose and fourteen main wheel bogies, seven per side, each with two wheels).

An-225 "Mriya" ("Mriya" is Ukrainian word for "dream) is also capable to transport other oversized objects/cargo. It is not a military aircraft, but it could find many military uses, because of the ability to transport cargo that no other aircraft is capable to.

The plane had the first flight in early 1988 and entered service in 1989. It's first flight took 75 minutes. After the cancellation of the Buran space program, the only An-225 built was stored in spring 1994, and it's engines were used for An-124s. In 2001 the aircraft was made airworthy again, and made it's new first flight on May 7. There were rumors that the European Space Agency had plans to launch the unmanned British HoTOL (Horizontal Take-Off and Landing) from the An-225, though these rumors appear to be unfounded. Although, some possibilities for deployment have already been found. Plenty of customers are to be found in the USA.

According to Bruce Bird, Director of the Charter Division of Air Foyle, parts of rocket launchers like the Delta and Atlas could be transported in the An-225. Lockheed's planned Venture Star could be transported on its back. Additionally the Mrija could serve as a launch platform for the X-34B. Furthermore big sections of aircraft could be transported in it. The complete assembled fuselage of a Boeing 737 can be fitted in the hold.

A second An-225 was partly built, but was stored before it was finished. It is possible that more aircraft of the type will be built, depending on market demand.

|

|

Other ESSENTIAL Files:

|

Repaint by JF

|

Tradewind Logistics PJ-DRU Float

(Also includes

TAL N411S 'Yukon Delta')

FS9

FSX

|

Beech D18S Amphibian/Float ~ Shupe & Co

Beech's most successful airliner, more than 9000 Beech 18s were built over an uninterrupted three decade long production run, and while many of those were built against wartime military contracts, vast numbers went on to see civil service.

The prototype Beech 18 first flew on January 15 1937. The design followed conventional design wisdom at the time, including twin radial engines, metal construction and taildragger undercarriage, while less common were the twin tail fins. Early production aircraft were either powered by two 225kW (300hp) Jacobs L6s or 260kW (350hp) Wright R760Es. The Pratt & Whitney Wasp Junior became the definitive engine from the prewar C18S onwards.

The demands of World War 2 significantly boosted the already successful Beech 18's fortunes, with 5000 built as C45s for the US Army Air Force for use as transports and multi engine pilot trainers.

Postwar, large numbers of C45s entered civil service, while Beech resumed production of the C18S. Progressive development resulted in the D18S of 1946, the Continental powered D18C of 1947, the E18S of 1954, the G18S from 1959 and the H18 with optional tricycle undercarriage from 1962. Beech production ceased in 1969.

The Beech 18 has also been the subject of numerous conversions. Volpar has offered tricycle undercarriage conversions, conversions with TPE331 turboprops and stretched and TPE331 powered conversions (described in the specifications above). Hamilton meanwhile converted Beech 18s as Westwinds with Pratt & Whitney Canada PT6 turboprops and also offered stretches.

|

|

Other ESSENTIAL Files:

|

Repaint by JF

Panel ~ FSX vesrions include mod panel

Must read the docs !

|

|

PJ-ADK'Lucy'

|

Boeing

727-200F ~ Vans

The

727-100 had been in service barely a year when Boeing

began serious consideration of a stretched, greater capacity

development.

This resulted in the 727-200, which Boeing announced it

was developing in August 1965. The 727-200 was essentially

a minimum change development of the 100, the only major

change being the 6.10m (20ft) fuselage stretch, which

increased maximum seating to 189 passengers. The 727-200's

stretch consisted of two 3.05m (10ft) plugs, one forward

and one rear of the wing. Otherwise the 727-100 and 200

shared common engines, fuel tank capacity and the same

maximum takeoff weight.

The first flight of the 727-200 occurred on July 27 1967,

with certification granted in late November that year.

The -200 was placed into service by launch customer Northeast

Airlines (this airline was later acquired by Delta) the

following month, by which time total 727 orders for both

models had exceeded 500.

The 727-200 helped broaden the sales appeal of the 727

considerably and snared significant sales. However the

200 was restricted by its relatively short range, due

to it having the same fuel capacity as the 727-100, so

Boeing developed the increased range Advanced 727-200.

First flown in March 1972 changes introduced on the Advanced

model included increased fuel capacity, and thus range,

the option of more powerful engines, quieter engine nacelles

and strengthened structure. The Advanced remained the

primary 727-200 production model until production ceased

in 1984.

The 727-200 remains popular with passengers and pilots

but it does not meet Stage 3 noise requirements. To overcome

this a number of hushkit programs are on offer while Valsan

converted 23 727s to its Stage 3 compliant Quiet 727 standard

(before the company collapsed). This retrofit included

installing JT8D-217s on the outer pylons and acoustic

treatment of the centre engine. Other 727s have been fitted

with winglets for improved performance.

|

|

|

Other Suggested Files:

|

Repaint by Pat Hanna

PANEL & SOUND

aliased to default 737

|

|

PJ-SPA

'Fleetwing'

FS9

ONLY

|

Boeing

737-300SF ~ FFX

The

737-300 is the first of the three member second generation

CFM56 powered 737 family, which also comprises the stretched

737-400 and shortened 737-500. The success of the second

generation Boeing 737 family pushed sales of the mark

to over 3000, a record for a commercial jetliner.

Despite

the all new engines and the 2.64m (104in) fuselage stretch,

the 737-300 retains 80% airframe spares commonality and

shares the same ground handling equipment with the 737-200.

A number of aerodynamic improvements were incorporated

to further improve efficiency including modified leading

edge slats and a new dorsal fin extending from the tail.

Another feature was the flattened, oval shaped engine

nacelles, while the nosewheel leg was extended to increase

ground clearance for the new engines. Other internal changes

include materials and systems improvements first developed

for the 757 and 767 programs, including an early generation

EFIS flightdeck (with four colour CRT screens).

The

737-300SF passenger to freighter conversion is by Israel

Aircraft Industries (IAI), Bedek Aviation Group.

|

|

|

Other Suggested Files:

Updated aircraft.cfg

file (courtesy of Karl Hajek)

|

Repaint by JF

INCLUDES PAUL SCARRATT'S

CLASSIC PANEL

|

PJ-HPW 'Pan American Trader' Tradewind Logistics 737

Includes PJ-GDI 'Lady Marion' Tradewind Caribbean 737

FS9 FSX

|

Boeing

737/700ER-ERF/800ER/900ER/ ~ TDS

Boeing's

Next Generation 737-800 and 737-900 are the largest members

of the strong selling 737 family. Unlike the other Next

Generation 737s, the -800 and -900 introduce new fuselage

lengths, extending 737 single class seating range out

to 189, compared with 100 in the original 737-100.

Like the -600 and -700, the -800 and -900 feature the

Next Generation improvements including more efficient

CFM56-7B turbofans, the new wing with greater chord, span

and wing area, larger tail surfaces and the 777 style

EFIS flightdeck with six flat panel LCDs which can present

information as on the 777 or as on the 737-300/400/500

series, the latter allowing a common pilot type rating

for the two 737 families. A HUD is optional. BBJ style

winglets are offered as an optional feature for the -800

|

FS9 and FSX

|

|

Repaints by Meindert Wijnberg

FSX version includes enhanced VC

|

PJ-BHF Tradewind Logistics

Includes

N738TA 'Iñupiat' Tradewind Alaska

N789TA 'Yupik' Tradewind Alaska Combi

N367TA '' Northern Air Cargo (Op by Tradewind Alaska Cargo)

FS9 and FSX

|

Boeing

737-800SF ~ TDS

Aeronautical Engineers, Inc. (AEI) is pleased to announce that it

has formally launched both Passenger to Freighter and Passenger to Combi Conversion Programs

for the Boeing 737-800. Both programs have been studied for the past year and will be marketed

as B737-800SF (Special Freighter) and B737-800C (Combination Passenger and Freighter). The

program development costs are being fully funded by AEI. The modification touch labor will be per-

formed at Commercial Jet’s Miami Florida facility, which is one of five authorized AEI Conversion

Centers worldwide.

AEI will make both conversions available at all authorized AEI Conversion Centers shortly after is-

suance of the STC by the FAA and expects the initial development and certification to take two and

a half to three years. After the initial FAA STC issuance, AEI plans to certify both conversion pro-

grams with the EASA, CAAC, ANAC and Russian authorities.

Mr. Robert T. Convey, Vice President of Sales & Marketing, stated that “As with many successful

freighter conversion programs in the past, the 737-800 has now entered the “Zone of Conversion”

with the oldest units approaching 15 years of age.” He goes onto say: “This conversion program is

however unique when compared to past programs in that the 737-800 is still in production and its

replacement, the Boeing 737 MAX 8 is nearing entry into service. What this means is that owners

and operators will for the first time have access to modern narrowbody converted freighters.”

The AEI B737-800SF 12 Pallet Conversion will include;

- Twelve Main Deck Pallet Positions, Eleven 88”X125” full height AAA ULD’s plus one

53”X88”X64” Pallet or AEP/AEH or 60.4”X61.5” AKE/LD3 or 61.5”X88”X56”H AYY

- Up to 52,000 lb (23,587 kg) Main Deck Payload

- 86”x140” main deck cargo door

- Highest position weights in the industry

- Low profile 1.25” Ancra International Cargo Loading System

- 9g rigid cargo / smoke barrier with sliding door

- High reliability, 28VDC, independent hydraulic system

- Up to 5 Supernumerary Seats

The AEI B737-800C Conversion will include;

- Five Main Deck Pallet Positions 88”X125” full height AAA ULD’s

- 90 passengers in coach class configuration

- Up to 30,000 lb (13,608 kg) Main Deck Payload

- 86”x140” main deck cargo door

- Highest position weights in the industry

- Low profile 1.25” Ancra International Cargo Loading System

- 9g rigid cargo / smoke barrier with sliding door

- High reliability, 28VDC, independent hydraulic system

- Up to 5 Supernumerary Seats

|

|

Other Suggested Files:

|

Repaint by JF

Includes VC

and 2D Panel

|

Now Version 2

PJ-TGP 'Fair Trade Ambassador'

Includes N746TA 'Kiibuyat Trader'

FS9

FSX

|

Boeing

747-400ERF v4 ~ Posky

The

747-400 is the latest, longest ranging and best selling

model of the 747 family.

Boeing launched

the 747-400 in October 1985 and the first development

aircraft first flew on April 29 1988. US certification

(with PW-4000s) was awarded in January 1989.

The 747-400 externally resembles the -300, but it is a

significantly improved aircraft. Changes include a new,

two crew digital flightdeck with six large CRT displays,

an increased span wing with winglets (the -400 was the

first airliner to introduce winglets), new engines, recontoured

wing/fuselage fairing, a new interior, lower basic but

increased max takeoff weights, and greater range.

The

latest model is the 747-400ER, which was launched on November

28, 2000 when Qantas placed an order for 6. The -400ER

has the same size as the -400, but has more range or payload

capability. The MTOW was increased by 15,870kg (35,000lb)

to 412,770kg (910,000lb), giving a further range of 805km

(435nm) or a 6800kg (15,000lb) greater payload. The -400ER

also features a wholly new cabin interior with larger

luggage bins, and several flight deck improvements.

The -400ER incorporates the strengthened wing, body, and

landing gear of the -400F, plus an auxiliary fuel tank

in the forward cargo hold, and an optional second one.

Operators who don't need these can remove them both, gaining

additional cargo volume.

|

|

Other Suggested Files:

|

Repaint by Meindert

Wijnberg

FSX version aircraft aliased to the default 747 VC

|

PJ-BIG 'Giganticar'

FS9

FSX

|

Boeing

747-400LCF v4 ~ Posky

Boeing Commercial Airplanes announced on October 13, 2003 that due to the length of time required by marine shipping, air transport will be the primary method of transporting parts for the 787 (then known as the 7E7). Three used passenger 747-400 aircraft were to be converted into an outsize configuration in order to ferry sub-assemblies from Japan and Italy to Charleston, South Carolina and then to Everett, Washington for final assembly. The Large Cargo Freighter has a bulging fuselage similar in concept to the Super Guppy and Airbus A300-600ST Beluga outsize cargo aircraft, which are also used for transporting wings and fuselage sections. It can hold three times the volume of a 747-400F freighter.

The LCF conversion was partially designed by Boeing's Moscow bureau and Boeing Rocketdyne with the swing tail designed in partnership with Gamesa Aeronautica of Spain. Modification is being carried out in Taiwan by Evergreen Aviation Technologies Corporation, a joint venture of Evergreen Group's EVA Air and General Electric.Boeing has already acquired the four second-hand 747-400s; one former Air China aircraft, two former China Airlines aircraft, and one former Malaysia Airlines aircraft. [Registrations N747BC (Serial 25879), N780BA (Serial 24310), N249BA (Serial 24309), and N718BA (Serial 27042).

It is much more economical for Boeing to buy used 747s and convert them than to construct these planes from scratch. The LCF is not a Boeing production model and will not be sold to any customers or see any airliner operation, and will be for Boeing's exclusive use. Another reason for modifying existing planes is the minimal regulation and flight testing required by authorities such as the Federal Aviation Administration. If the 747 LCF were produced entirely within Boeing, it would face years of development and testing in the same manner as the upcoming Boeing 747-8. Rules on airworthiness allow for the faster approval of modifications to existing aircraft that are already approved than would be the case for the approval of brand new aircraft designs.

In June 2006, the completion of the first DBL-100 cargo loader used for loading 787 parts into the 747 LCF was announced by Boeing. These loaders were designed and built by Canadian firm, TLD at its facility at Sherbrooke, Quebec and are the longest in the world at 118 foot 1 inch.

The first conversion, which drew comment because in addition to its ungainly shape, it also remained in this unpainted configuration for a long time.

In December 2006, Boeing announced the LCF would also be known as the Dreamlifter, a reference to the 787's name, the Dreamliner. It unveiled a standard livery for the aircraft that included a Dreamlifter logo reminiscent of the 787's Dreamliner logo.

The certification was to be in early 2007 however it was pushed back to June 2007. The plane had its winglets removed after excess vibration and other handling characteristics need to be dealt with prior to final certification. In the meantime as part of the flight test program, LCF delivered major sections of the 787 from partner sites around the world to the Boeing factory in Everett, WA for final assembly. The 747 LCF was granted type certification on June 2, 2007 from Federal Aviation Administration. The Dreamlifter completed 437 flight-test hours and 639 hours of ground testing since its first flight on Sept. 9, 2006.

The 747 LCF's unusual appearance has drawn comparisons to the Oscar Mayer Wienermobile and the Hughes H-4 Hercules ("Spruce Goose"). Due to its ungainly form, and exacerbated by the fact that the need for immediate testing resulted in the first model remaining unpainted for some time, Boeing Commercial Airplanes president Scott Carson jokingly apologized to Joe Sutter, designer of the 747 that he was "sorry for what we did to your plane."

Boeing plans to acquire four 747 Dreamlifters. As of June 2008, three LCFs are complete and operational, and the fourth is to become operational in 2009.

|

|

Other Suggested Files:

|

Repaint by JF

FSX version aircraft aliased to the default 747 VC

|

|

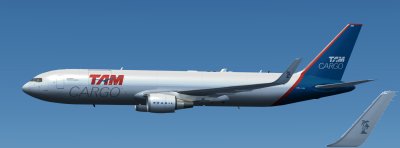

PJ-TNW

'Ocean Trader'

FS9

ONLY

|

Boeing

767-300F ER GE ~ Posky

Boeing

announced that it was developing a stretched development

of the 767-200 in February 1982.

The resulting 767-300 features a 6.42m (21ft 1in) stretch

consisting of fuselage plugs forward (3.07m/10ft 1in)

and behind (3.35m/11ft) the wing centre section. The flightdeck

and systems were carried directly over from the 767-200,

the only other changes were minor, and related to the

increased weights of the new version. Initially the max

takeoff weight was the same as the later 767-200ER.

The 767-300 flew for the first time on January 30 1986,

and was awarded certification and entered service in September

that year. The higher weight Extended Range ER version

flew on December 19 1986, while RollsRoyce RB-211-524G

engines became available from 1989. The range of the 767-300ER

has proven to be very popular with a number of airlines

using them for long range low density flights.

In 1993 Boeing launched the 767-300F General Market Freighter.

Changes include strengthened undercarriage and wing structure,

a cargo handling system, no cabin windows and a main deck

freight door. Capacity is 24 containers. The further stretched

767-400 is described separately.

|

|

|

Other Suggested Files:

|

Repaint by JF

Includes 2D

Panel

|

PJ-DHL

PJ-FDX

PJ-TAM

PJ-TPC

PJ-UPS

Wet Lease Aircraft - Operated by Tradewind Logistics

FSX with 2D Panel + 738VC

Textures should work with FS9 (model NOT Included)

FSX with Level-D 767 VC Merge

FSX with JF757 VC Merge

FSX with QW757 VC Merge

|

Boeing

767-300F ER SkySpirit 2010 v5

Boeing

announced that it was developing a stretched development

of the 767-200 in February 1982.

The resulting 767-300 features a 6.42m (21ft 1in) stretch

consisting of fuselage plugs forward (3.07m/10ft 1in)

and behind (3.35m/11ft) the wing centre section. The flightdeck

and systems were carried directly over from the 767-200,

the only other changes were minor, and related to the

increased weights of the new version. Initially the max

takeoff weight was the same as the later 767-200ER.

The 767-300 flew for the first time on January 30 1986,

and was awarded certification and entered service in September

that year. The higher weight Extended Range ER version

flew on December 19 1986, while RollsRoyce RB-211-524G

engines became available from 1989. The range of the 767-300ER

has proven to be very popular with a number of airlines

using them for long range low density flights.

In 1993 Boeing launched the 767-300F General Market Freighter.

Changes include strengthened undercarriage and wing structure,

a cargo handling system, no cabin windows and a main deck

freight door. Capacity is 24 containers. The further stretched

767-400 is described separately.

|

|

Other Suggested Files:

|

Repaints by JF

Includes 2D

Panel + Panel merge Options

|

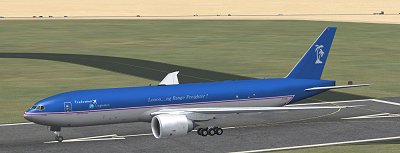

PJ-LRF 'Longreach Trader'

FS9

FSX

(Also includes Tradewind Alaska Cargo version N772TA)

|

Boeing

777-200LRF ~ Posky

Boeing's advanced widebody 777 twin incorporates more advanced technologies than any other previous Boeing airliner, and has been progressively developed into increasingly longer range developments.

The 777 was originally conceived as a stretched 767, but Boeing instead adopted an all new design. Notable 777 design features include a unique fuselage cross section, Boeing's first application of fly-by-wire, an advanced technology glass flightdeck with five liquid crystal displays, comparatively large scale use of composites (10% by weight), and advanced and extremely powerful engines. The 777 was also offered with optional folding wings where the outer 6m/21ft of each would fold upwards for operations at space restricted airports.

The basic 777-200 as launched in October 1990 was offered in two versions, the basic 777-200 (initially A-Market) and the increased weight longer range 777-200IGW (Increased Gross Weight, initially B-Market). The IGW has since been redesignated 777-200ER.

The 777-200 first flew on June 12 1994, with FAA and JAA certification awarded on April 19 1995. The FAA awarded full 180 minutes ETOPS clearance for PW4074 -200s on May 30 that year. First customer delivery was to United Airlines in May 1995. The first 777-200IGW/ER was delivered to British Airways in February 1997.

The 777-100X was a proposed shortened ultra long range (16,000km/8635nm) model, dropped in favour of the 777-200LR (originally 777-200X) design study. Boeing claims the 777-200LR will be the longest ranging airliner, capable of flying 16,417km (8865nm) - 18 hours flying time. It will achieve this with awesomely powerful 489kN (110,000lb) thrust GE90-110B1 turbofans, a significantly increased max takeoff weight and optional auxiliary fuel tanks in the rear cargo hold. Other changes include 2m (6.5ft) raked wingtips, new main landing gear, structural strengthening and optional overhead crew and flight attendant rest stations above the cabin. The 777-200LR was launched in 2000

|

|

Other Suggested Files:

|

Repaint by JF

Includes VC*

and 2D Panel

* FSX VC has nightime lighting issues

|

PJ-DRF 'Soño Transportadó' Tradewind logistics

Also

PJ-DRM 'Caribbean Vision' Tradewind Caribbean

N787TA 'Alaskan Vision' Tradewind Alaska

F-OHDL 'Pacific Vision' Tradewind Pacific

FSX

FSX (Aerosim Alias)

FS9

|

Boeing

787-800 ~ TDS

The Boeing 7E7 was announced on 29th January 2003 following the cancellation of the Sonic Cruiser. The aircraft was renamed the Boeing 787 in 2005.

This important design marked a major shift in technology for Boeing, which aimed for maximum fuel efficiency in a number of ways. Chief among these was a radical change of construction material, with much of the aircraft being built of carbon fibre reinforced plastic (CFRP). Additionally, the fuselage was produced as 'barrels' rather than sheets of material, reducing the number of fastenings required. This further increased the weight savings. Many of the aircraft's systems are now electrically operated, replacing the heavier hydraulic systems of earlier Boeing designs with lighter technology.

The engines are new designs with increased fuel efficiency. Both the General Electric GEnx and Rolls-Royce Trent 1000 designs are available. Boeing decided to use bleedless designs, another major change for aircraft of this class. Interestingly, Airbus decided not to use bleedless technology on its competing Airbus A350 design and it remains to be seen which approach offers the greatest benefits over the other. The rear engine nacelle has a distinctive rippled look which reduces noise as the engine exhaust and external air mix.

For passengers, there have been a number of technology improvements. Most noticeably, the windows are amongst the largest in a civil airliner and are lower on the fuselage than is usual, so that passengers have a better view downwards. The lighting system use LED technology allowing each customer great flexibility on the lighting schemes it can use. The pressurisation system features a lower cabin altitude than normal and allows increased humidity, both factors which will contribute to passenger comfort during a long flight.

With all these technology advances and a distributed manufacturing program that was very new to Boeing, it is not suprising that the program encountered a number of delays. However, the first aircraft was delivered to a customer, All Nippon Airways, in September 2011.

|

|

Other Suggested Files:

|

Repaint by JF

FSX version includes updated 738 VC

and 787 2D Panel

Also an option for Aerosim VC and sound alias

|

|

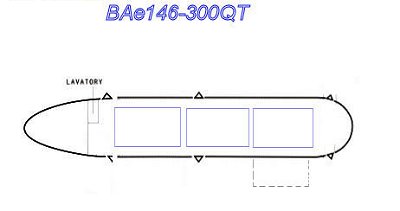

PJ-TQX'Nina

Simone'

PJ-TQI'Night

Hawk'

FS9

ONLY

Both in

same zip

|

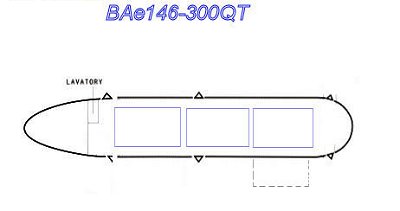

British

Aerospace BAe 146-300QT ~ ARNZ

The

BAe-146 family, which includes the Avro RJ and the cancelled

RJX (both described separately), is likely to remain Britain's

most succesful jet transport program, with 395 built.

In

August 1973 the then Hawker Siddeley Aviation announced

it was designing a short range quiet airliner powered

by four small turbofans with British government financial

aid. Under the designation HS-146, large scale development

lasted just a few months before a worsening economic recession

made the risk of the project seem unjustifiable. Development

then continued on a limited scale, but it was not until

July 1978 that the project was officially relaunched,

by which time Hawker Siddeley had been absorbed into the

newly created British Aerospace.

The

resulting BAe-146-100 made its first flight on September

3 1981. Certification was granted in early 1983 with first

deliveries following shortly afterwards in May 1983. A

VIP version was offered as the "Statesman" which

was ordered by the Royal Air Force as the BAe-146 CC2,

the standard transport version being the BAe-146 C1. An

air refuel receptacle equipped military version, the -100STA

flew in prototype form only.

The

BAe-146-200 is a stretch of the 146-100, and is essentially

similar to its smaller stablemate, but has a 2.39m (7ft

8in) longer fuselage, features 35% greater underfloor

cargo volume, has slightly different performance figures

and heavier weights. The stretch consists of five extra

fuselage frame pitches. The first BAe-146-200 made the

type's maiden flight on August 1 1982, while the UK Civil

Aviation Authority awarded the 146-200s type certificate

on February 4 the following year.

Versions

of the 146-200 include the -200QT Quiet Trader freighter,

which has been fairly succesful because of its low external

noise footprint, and the -200QC (Quick Change) passenger

or freight convertible.

The

146-300 is a further stretched derivative of the original

short fuselage BAe-146-100, but unlike the midsize 200

series, was not developed until later in the 1980s. The

first 146-300, an aerodynamic prototype based on the original

prototype 146-100, flew for the first time on May 1 1987,

with certification granted that September.

Like

the 146-200, a freighter version of the 300 series is

known as the 146-300QT Quiet Trader. The prototype -300

was converted to 146-301ARA configuration, an atmospheric

research aircraft operated by the Facility for Airborne

Atmospheric Measurements as a replacement for the previously

operated Hercules W2.

The

last of the original 146s were built in 1993, with the

series succeeded by the Avro 146-RJ family, described

separately.

|

|

|

Other Suggested Files:

|

Repaint by JF

|

|

PJ-FCR

FS9

ONLY

|

De

Havilland DHC-6 300 Cargo ~ Premiercraft

Canada's

most successful commercial aircraft program with more

than 800 built, the Twin Otter remains popular for its

rugged construction and useful STOL performance.

The

Series 300 was introduced from the 231st production aircraft

in 1969. It featured the lengthened nose, but also introduced

more powerful engines, thus allowing a 450kg (1000lb)

increase in takeoff weight and a 20 seat interior. Production

ceased in late 1988. In addition, six 300S enhanced STOL

performance DHC-6-300s were built in the mid 1970s.

|

|

|

Other ESSENTIAL Files:

DH6_GAU.ZIP

DH6_SND.ZIP

Texture UPDATE

|

Repaint by JF

Panel ~ Included

|

PJ-ECY Tradewind Logistics

For FS9 and FSX

|

Embraer

EMB-110 Bandeirante ~ AEROPROYECTO

The Embraer EMB-110 Bandeirante, or `Bandit', remains Embraer's most successful commercial aircraft program.

Design of the EMB-110 was undertaken in response to a Brazilian Ministry of Aeronautics specification for a general purpose light transport suitable for military and civilian duties. The new design was developed with the assistance of well known French designer Max Holste, and the first of three YC-95 prototypes flew for the first time on October 26 1968.

Embraer (or Empresa Brasilera de Aeronautica SA) was established the following year, and development and production of the C95 became one of the company's first responsibilities. The first production standard EMB-110 Bandeirante (Portuguese for Pioneer) flew on August 9 1972, and the first entered airline service in April 1973.

Bandeirante models include the 12 seat transport EMB-110, the aerial photography EMB-110B and maritime patrol EMB-111 for the Brazilian air force; the initial airline version, the 15 seat EMB-110C; the seven seat EMB110E executive transport; 18 seat enlarged EMB-110P; convertible passenger/freight EMB110P1 with larger rear door; the EMB-110PA which replaced the 110P as the standard passenger aircraft from 1983 and introduced dihedral to the tailplane among other minor improvements; the EMB-110P1K and EMB-110K SAR military equivalents to the P1A; the EMB-110P2 commuter with seating for up to 21; the EMB-110P2A which replaced the P2 and introduced the same changes as the P1A; and the EMB-110P1A/41 and EMBP2A/41 versions of the P1A and P2A recertificated to US FAA SFAR41 standards with higher weights.

Production of the Bandeirante ceased in May 1990, the final aircraft being delivered to the Brazilian Air Force. Today the Bandeirante's virtues of reliability and good operating economics means that it remains popular with its operators.

|

|

Other ESSENTIAL Files:

|

Repaints by JF

|

|

PJ-FEK

Included

TDM version PJ-FED 'West

Peak'

Essential

Texture Update - Grey Spinners

or

Essential

Texture Update - Blue Spinners

or

Essential

Texture Update - Black Spinners

|

|

Fokker

50 ~ Dreamwings

The

Fokker 50 was the successor to Fokker's highly successful

and long running F-27 Friendship.

Fokker announced

it was developing the 50 seat Fokker 50, together with the

100 seat jet powered Fokker 100, in November 1983. The Fokker

50 is based on the fuselage of the F-27-500 Friendship,

but incorporates a number of key design changes. Foremost

of the improvements was the new generation Pratt & Whitney

Canada PW125 turboprops driving advanced six blade props,

giving a 12% higher cruising speed and greater fuel economy,

and thus range. Other improvements include new avionics

and an EFIS glass cockpit, limited use of composites, small

`Foklet' winglets, and more, squared, main cabin windows.

Two prototypes

were built based on F-27 airframes (despite the fact that

over 80% of Fokker 50 parts are new or modified), the first

flying on December 28 1985. The first production aircraft

flew on February 13 1987, certification was granted in May

1987, and first customer delivery, to Lufthansa Cityline,

was during August that year.

The basic Fokker

50 production model is the Series 100. With three, instead

of four doors, the Series 100 is designated the Series 120.

The hot and high optimised Series 300 has more powerful

PW127B turboprops, and was announced in 1990. It has higher

cruising speeds and better field performance, particularly

at altitude.

The only significant

development of the Fokker 50 to see the light of day was

the Fokker 60 Utility, a stretched utility transport version

ordered by the Royal Netherlands Air Force. Fokker built

four for the Netherlands air force and looked at offering

a passenger variant. The Fokker 60 was stretched by 1.62m

(5ft 4in).

Fokker collapsed

due to financial problems on March 15 1996 and the last

Fokker 50 was delivered to Ethiopian Airlines in May 1997.

|

|

|

Other Suggested Files:

|

Repaint by JF

Panel ~ 2D by Espen

Øijordsbakken included

Essential to read

the docs !

|

|

PJ-GLS

FS9

ONLY

|

Gates

Learjet 25D ~ Lars Roennig

One

of the world's largest, fastest, best selling and well

known series of business jets, the Learjet family began

with the original six to eight seat Lear Jet 23 which

first flew on October 7 1963.

The 23 originated in Switzerland, where William P. Lear

had formed the Swiss-American Aviation Corporation (SAAC)

in 1960 to manufacture a twin-jet high-speed executive

aircraft, the SAAC-23. This aircraft was designed and

conceived by Dr.eng. Hans-Luzius Studer, who previously

had developed the FFA P-16 fighter. The aerodynamics and

many other characteristics of the 23 were taken over from

the P-16. Although it was originally planned to manufacture

at least the first 25 Lear Jets in Switzerland, production

was transferred to the United States, where Lear had founded

Lear Jet Corporation.

The diminutive Model 23 pioneered an entirely new market

segment for the light business jets, and proved very successful.

The first production 23 was delivered in October 1964,

but was replaced by the improved Model 24 in 1966 after

105 had been built. The 24, which introduced uprated engines

and a number of detail changes, first flew in February

1966 and was delivered from the middle of that year. Developments

of the 24 included the 24D, E and F, introducing improvements

such as increased weights, thrusts, and range.

The Learjet 25 introduced a 1.27m (4ft 2in) fuselage stretch

allowing seating for up to eight passengers and was first

flown on August 12 1966, and, like the 24, a number of

subsequent developments were built, including the B, C,

and D.

In 1966 the name of the manufacturer changed to Lear Jet

Industries, and in January 1970 Gates Rubber Company,

who had bought a controlling interest, changed the name

again, to Gates Learjet Corporation.

The unsuccessful Gates Learjet 28 and 29 Longhorns are

based on the 25 but introduced a new increased span wing

fitted with winglets, which improved fuel efficiency and

overall performance, particularly payload range and fuel

economy. The Longhorn 28 seats up to eight passengers,

the similar dimensions Longhorn 29 sacrifices two seats

for extra range. Production of the family ceased in 1982.

Learjets are known for their tight accomodation. Max internal

cabin width is just 1.50m (4ft 11in), max height 1.32m

(4ft 4in)

|

Powerplants

23 - Two 12.7kN (2850lb) General Electric CJ610-4 turbojets.

25D/29 - Two 13.1kN (2950lb) CJ610-8As.

Performance

23 - Max speed 860km/h (465kt), max cruising speed 850km/h

(460kt), economical cruising speed 817km/h (440kt). Range

with max fuel and reserves 2660km (1436nm).

25D - Cruising speed 860km/h (465kt). Range with four

passengers and reserves 2663km (1438nm).

29 - Max speed 883km/h (477kt), max cruising speed 836km/h

(452kt), economical cruising speed 756km/h (408kt). Service

ceiling 51,000ft. Range with four passengers, max fuel

and reserves 2550km (1376nm).

Weights

23 - Empty 2974kg (6550lb), max takeoff 5675kg (12,500lb).

25D - Empty equipped 3465kg (7640lb), max takeoff 6805kg

(15,000lb).

29 - Empty 3730kg (8224lb), max takeoff 6805kg (15,000lb).

Dimensions

23 - Wing span 10.84m (35ft 8in), length 13.18m (43ft

3in), height 3.73m (12ft 3in). Wing area 21.5m2 (231.77sq

ft).

25D - Same except for length 14.50m (47ft 7in).

29 - Same as 25 except for wing span 13.35m (43ft 10in).

Wing area 24.6m2 (264.5sq ft).

Capacity

23/24 - Flightcrew of two. Max seating in main cabin for

six, typical seating for four.

25/28 - Flightcrew of two. Main cabin seating for up to

eight passengers.

29 - Flightcrew of two and seating for six passengers

|

|

|

Other ESSENTIAL Files:

|

Repaint by JF

Panel by Horst Paetzold and JF

|

PJ-CCJ

FS9 ONLY

|

Lockheed L130J Hercules ~ M Stone

Lockheed's L-100 freighters are the civil equivalents of the venerable military C-130 Hercules, and have proven to be of great utility, particularly in undeveloped countries.

Lockheed initiated design of the Hercules in response to a 1951 US Air Force requirement for a turboprop powered freighter. This resulted in the C-130 Hercules, which first flew in prototype form on August 23 1954. Design features included the high mounted wing, four Allison 501/T56 turboprops and the rear loading freight ramp. The USAF ordered the C-130 into series production in September 1952, and since that time more than 2500 have been built.

The C-130's appeal to freight operators led Lockheed to develop a civil version. The first commercial versions were based on the C-130E model, and a demilitarised demonstrator first flew in April 1964. This initial civil development, the L-100 (L-382), was awarded civil certification in February 1965. This model was soon followed up by the series L-100 (L-382B), which introduced an improved freight handling system.

Sales of these initial versions were slow, leading Lockheed to develop the 2.54m (8ft 4in) stretched L-100-20 (L-382E), which offered better freight capacity and operating economics. The L-100-20 was certificated in October 1968, but was soon followed by the even longer L-100-30 (L-382G). The -30 was 2.03m (6ft 8in) longer than the -20, first flew in August 1970, and was delivered from December that year. Most civil Hercules sales have been of the L-100-30 variant. Although basically a civil aircraft, several L-100s are in service with military operators, e.g. in Algeria, Gabon and Kuwait. The last L-100 was built in 1992, while the last military Allison 501/T56 powered C-130 was delivered in 1996.

The L-100J would be a commercial derivative of the new generation C-130J Hercules II. Improvements would include new 3425kW (4591shp) Rolls-Royce (Allison) AE-2100D3 advanced turboprop engines driving six blade props, two crew EFIS flightdeck and significantly lower maintenance and operating costs. The C-130J first flew on April 5 1996, while US FAA civil certification was awarded in September 1998. The L-100J would be based on the stretched fuselage C-130J-30, but in 2000 the program was frozen as Lockheed martin focussed on the military variants.

|

|

Other ESSENTIAL Files:

|

Repaint by Meindert

Wijnberg

Panel ~ Included

|

PJ-VJM

'Palo Seco'

(Also

includes N187TA 'Anaktuvuk Pass')

FSX ONLY

|

Lockheed L188 Electra II ~ KBT

Lockheed's Electra provided a number of airlines with their introduction to turbine powered aircraft. Today it remains popular with freight operators.

The Lockheed L-188 Electra was developed to meet a 1954 American Airlines requirement for a domestic short to medium range 75 to 100 seat airliner. In June 1955 American awarded Lockheed an order for 35 such aircraft. Lockheed's design, the L-188, was a low wing, four turboprop powered aircraft. Many other airlines shared American's interest in the L-188, and by the time the first prototype flew on December 6 1957, the order book stood at 144. Service entry was with Eastern Airlines (due to a pilot's strike at American) on January 12 1959.

However, any optimism Lockheed felt about a strong sales future would have been short lived, as a number of crashes in 1959 and 1960 (two of which where the aircraft broke up in flight) contributed to a number of order cancellations.

As an interim measure following the crashes, speed restrictions were imposed on Electras. Investigations uncovered a design defect with the engine mountings where the wing would shake and eventually break up. Lockheed undertook a significant modification program where the nacelles, nacelle mountings and wing structure were strengthened, and the speed restrictions were eventually lifted in 1961. After that the Electra proved reliable and popular in service, but the damage had been done and production wound up in 1961 after 170 had been built.

Lockheed built two basic versions of the Electra. The L-188A was the basic production aircraft, and accounted for most Electra sales. The L-188C entered service with KLM in 1959 and had greater fuel capacity and higher weights, and thus improved payload range performance.

The Electra also forms the basis for the hugely successful P-3 Orion long range maritime surveillance aircraft of which more than 600 have been built.

Most Electras currently in service are configured as freighters. From 1967 Lockheed converted 41 Electras to freighters or convertible freighter/passenger aircraft, fitting a strengthened floor and a large cargo door forward of the wing on the left side. Other companies have also converted Electras to freighters. However, a small number remain in passenger service.

|

|

Other ESSENTIAL Files:

|

Repaint by Francisco

Aguiar

Panel ~ Included

Must read the docs

!

|

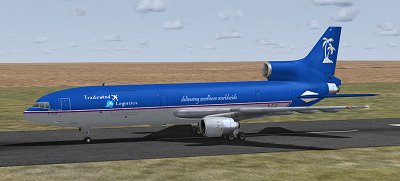

PJ-LJF 'Pacific Trader'

-200F

FS9 - FSX (includes TAC)

|

Lockheed Tristar ~ HJG

The Lockheed TriStar was the second widebody airliner to be launched, and although it was dogged with early financial and development problems, particularly with the engine, it went on to gain an excellent reputation in service for its reliability, economy of operation and low noise emissions.

The L-1011 TriStar was the last Lockheed airliner to be developed and was launched in March 1968 in response to an American Airlines requirement (that also resulted in the DC-10) for a large capacity medium range airliner. Lockheed initially studied a twin engined layout, but it was decided that three engines would be necessary to ensure it could takeoff at max weights from existing runways.

Work on the L-1011 prototype began early in 1969, resulting in a November 16 1970 first flight. The engine choice of Rolls-Royce's advanced three shaft design RB211 however dogged the TriStar's early career. Rolls-Royce went bankrupt in February 1970 largely due to higher than estimated RB211 development costs, severely harming both Lockheed and the TriStar sales program. The problems were able to be resolved after the British government nationalised Rolls-Royce, guaranteeing the supply of production engines. Despite the initial problems the RB211 proved to be extremely reliable and efficient in service and grew into a family of variants.

The first L-1011 model that entered service with Eastern and TWA in April 1972 was the initial domestic L-1011-1 (which was built in greater numbers than any other TriStar variant). Subsequent models to be developed were the -100 with more fuel and higher weights, the -200 with higher thrust engines, and the long range shorter fuselage -500, described separately.

Production ceased in 1983, when 250 had been built. The prototype was sold to be broken up for spares in 1986.

Many aircraft were converted to improved models: the -50 with a higher MTOW and strengthened fuselage, wings, and undercarriage, the -150 with a higher MTOW, the -250 with RB211-524B4 engines (as on the 500) for US carrier Delta, a small number to freighters with a large cargo door as -1(F) and -200(F), and quite a few to -100 and -200.

An ex Air Canada TriStar 100 was converted in 1992 by Marshall of Cambridge (Engineering) Ltd for Orbital Sciences Corporation as the "Stargazer" flying satellite launcher. After launching the Pegasus Air-Launched Space Booster from the TriStar, the Pegasus itself launched a satellite into low Earth orbit.

Another TriStar 100, ex Worldways Canada, was converted in 1995/1996 by Lockheed Aeromod Center to a flying hospital for Operation Blessing International Relief & Development Corporation, a non-profit humanitarian organisation. Apart from the hospital equipment, the aircraft is fitted with systems to be independent from local ground-based equipment.

Approximately 156 TriStars remained in service in 1998, of which 122 were standard fuselage models. In 2000 this number had gone down to about 137, of which 109 standard fuselage models, and at the end of 2002 this had further dropped to 51 active TriStars, of which 23 standard fuselage ones.

|

|

|

Repaints by Jack Ford

|

|

PJ-

DCA 'Colombian Trader'

PJ-

DCB 'African Trader'

PJ-

DCE 'Capt. Dale Langer'

FS9

|

MD

DC-8-73F ~ HJG

The

successful DC-8 Super 60 airliners are stretched developments

of the DC-8 Series 50. The Super 70s in turn have been

re-engined with CFM56 high bypass turbofans.

Douglas

announced the DC-8 Super Sixty in April 1965. The first,

a DC-8-61, took to the skies for the first time on March

14 1966, followed by the first flights of the DC-8-62

on August 29 1966 and the DC-8-63 on April 10 1967. The

DC-8-61 differed from the earlier DC-8-50 in having two

fuselage plugs which increased length by 11.18m (36ft

8in), increasing max seating capacity to 259 (the largest

of any single aisle airliner prior to the 757-300) and

underfloor freight capacity by 80%. Intended for domestic

operations, its max takeoff weight was identical to the

DC-8-50. The Super 62 was intended for long range operations

and featured only a modest 2.04m (6ft 8in) stretch compared

to the Series 50, greater wing span, revised engine nacelles

and pylons and significantly increased fuel capacity.

The Super 63 meanwhile combined the DC-8-61's fuselage

with the DC-8-62's wings. It was the final DC-8 variant

in production, and the last was delivered in May 1972.

McDonnell

Douglas initiated a reengining program of Super 60 series

aircraft with CFM International CFM56 engines in the early

1980s, known as the Super 70 Series. The first converted

airframe flew in August 1981. The Super 70 aircraft are

considerably quieter than their predecessors, with better

fuel economy and greater range.

It

should be mentioned that a considerable amount of DC-8

Super series have reached over 100.000 flight hours. Only

very few aircraft have achieved

Powerplant:

Four 97.9kN (22,000lb) CFM International CFM562C5s.

Performance:

Max cruising speed 887km/h (479kt), economical cruising

speed 850km/h (459kt). Range with max payload (Super 73)

8950km (4830nm).

Weights:

Operating empty 75,500kg (166,500lb), max takeoff 162,025kg

(355,000lb).

Dimensions:

Wing span 45.23m (148ft 5in), length 57.12m (187ft 5in),

height 12.92m (45ft 5in). Wing area 271.9m2 (2927sq ft).

Capacity:

Flightcrew of three. Super70 freighters payload between

40,405kg (89,000lb) and 49,585kg (109,217lb).

|

|

|

Recommended updates:

FDE features various

improvements HERE

Panel

features various improvements HERE

|

Repaint by JF

PANEL ~ with photoreal

bmps included

The panel uses a combination

of gauges of many freeware authors to whom we give our thanks

Based

on real world AOM data by Karl Hajek

|

|

PJ-

TBX

FS9

& FS2002 with mods - see docs

TEXTURES

ONLY - You need to have

Tradewind

Air Lease TF-BOX

already

installed

|

MD

DC-10-30F ~ SGA

Designed

in response to the same American Airlines requirement

as the Lockheed TriStar, the DC-10, despite a sometimes

troubled past, was the more successful of the two widebody

trijets.

Although originally conceived as a twinjet, the DC-10

gained a third engine at the base of its vertical tail

to meet an American Airlines requirement that the aircraft

be capable of operating from existing runways. The DC-10

subsequently was launched in February 1968 with orders

from American and United. First flight took place on August

29 1970

Designed

in response to the same American Airlines requirement

as the Lockheed TriStar, the DC-10, despite a sometimes

troubled past, was the more successful of the two widebody

trijets.

Although originally conceived as a twinjet, the DC-10

gained a third engine at the base of its vertical tail

to meet an American Airlines requirement that the aircraft

be capable of operating from existing runways. The DC-10

subsequently was launched in February 1968 with orders

from American and United. First flight took place on August

29 1970

|

|

| Other

Suggested Files:

The panel is configured

for use with the Delco Carousel IV-A Inertial Navigation System

Gauge CIVA140.zip

required available

from flightsim.com and other locations

Optional but recommended:

aircraft.cfg

update

based on real world AOM data by Karl Hajek

|

Repaint by JF

PANEL ~ with photoreal

bmps included

The panel requires some

mods for FS2002 compatibility - see docs

|

|

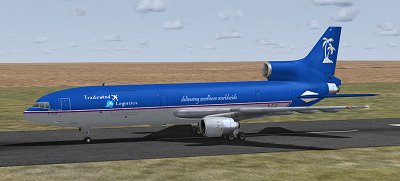

N114TL

'Celestial Traveller'

Leased

from the Boeing Corp.

FS9

& FS2002 with mods - see docs

Updated

aircraft.cfg

file (courtesy of Karl Hajek)

|

MD

MD-11F ~ iFDG v1.5

The

MD-11 is a modernised, slightly stretched and re-engined

development of the DC-10 trijet.

Launched

on December 30 1986 (following a launch order from British

Caledonian for three placed earlier that month), the MD-11

was the result of a two year study to find a replacement

for the DC-10. First flight occurred on January 10 1990,

certification was granted in November that year, and the

first one was delivered on December 7 1990 to Finnair.

Compared

to the DC-10, the MD-11 features a 5.71m (18ft 9in) fuselage

stretch, winglets, modified tail with less sweepback,

an advanced two crew six screen EFIS flightdeck, restyled

main cabin interior and new engine options. Variants offered

were the longer range MD-11ER available from early 1996,

MD-11F freighter, MD-11C Combi and MD-11CF convertible

passenger/freighter models.

McDonnell

Douglas at various times proposed MD-11 developments aimed

at increasing seating through stretches and underfloor

panorama deck seating. In 1996 MDC looked closely at the

MD-XX, MD-11 variants with a new wing. Two versions were

proposed, one with the standard MD-11 fuselage and a 15,565km

(8400nm) range, the other a stretched 375 seater. These

were not launched.

In

November 1997 following the Boeing/McDonnell Douglas merger

Boeing announced that the MD-11 would be retained in production,

primarily as a freighter. However in June 1998 Boeing

reversed that decision, saying that due to a lack of market

demand production would be wound up. The last MD-11 built,

a MD-11F for Lufthansa cargo, was delivered February 22

2001.

|

|

| Other

Suggested Files:

|

Repaint by JF

PANEL ~ with photoreal

bmps included

The panel is FS9 ONLY

|

|

PJ-YSC

(with APU) Cargo

PJ-YSF

Cargo

(Also

includes PJ-YSP TDM Pax and N116TA TA Combi)

52Mb

|

NAMC

YS-11 ~ AFG

The

only Japanese airliner to enter production since WW2,

the YS11 achieved a degree of success in its domestic

market and in North America.

The

YS11 was a product of the Nihon Aircraft Manufacturing

Company (or NAMC), a consortium of Fuji, Kawasaki, Mitsubishi,

Nippi, Shin Meiwa (now Shin Maywa) and Showa. NAMC formed

on June 1 1959 to design and develop a short to medium

range airliner, with particular attention being paid to

meeting the specific operating requirements of the Japanese

domestic airlines.

NAMC

selected the RollsRoyce Dart over the Allison 501 to power

the new airliner. Fuji was given responsibility for the

tail unit, Kawasaki the wings and engine nacelles, Mitsubishi

the forward fuselage and final assembly, Nippi the ailerons

and flaps, Shin Meiwa the rear fuselage and Showa the

light alloy honeycomb structural components.

The

YS11 first flew on August 30 1962 (a second prototype

flew that December), and was awarded Japanese certification

in August 1964. By that time the first production aircraft

were under construction, and the type entered service

with Toa Airways (now JAS) in April 1965. Initial production

was of the YS11100, the follow up YS11A200 (first flight

November 1967) was designed for export markets and featured

an increased max takeoff weight. The YS11A300 was a combi

passenger/freight model, while the YS11A400 was a pure

freighter with a forward freight door.

The

YS11A500, 600 and 700 were equivalent to the 200, 300

and 400, but with a 500kg (1100lb) greater max takeoff

weight. Production ceased in February 1974.

By

late 1998 66 YS11s remained in commercial service. The

largest operators were All Nippon (6) and Japan Air Commuter

(12).

|

|

|

Other ESSENTIAL Files:

|

Repaint by JF

Panel ~ Included

Must read the docs

!

|

PJ-TDY 'Pride of Martinique'

Includes N366TA 'Sasignan'

FS9 - FSX

|

Shorts 360 ~ Premier Aircraft Design

The Short 360 is a stretched, larger capacity and improved 36 seat derivative of the 30 seat Short 330.

The relative success of the rugged Short 330 prompted the Northern Ireland based manufacturer to study and subsequently develop a stretched derivative. Short announced it was developing the new airliner in mid 1980, and a prototype 360 flew for the first time almost a year later on June 1 1981.

The first production 360 flew in August 1982 and certification was awarded on September 3 that year. The 360 entered service with Suburban Airlines in the US in November 1982.

The two Short airliners are very close in overall dimensions and size, but the later 360 is easily identified by its new conventional tail unit mounted on a revised rear fuselage. The 360 is also 91cm (3ft) longer than the 330, allowing two more seat rows and six extra passengers to be carried, while the extra length reduces drag. Power is supplied by two Pratt & Whitney PT6A65Rs, and the 360's wing span is slightly greater. Otherwise the 330 and 360 are very similar, and share a high degree of commonality.

Short marketed a number of 360 developments, the first of which was the 360 Advanced with 1062kW (1424shp) PT6A65ARs. The 360 Advanced was introduced in late 1985, but was soon followed by the further improved 360300, which entered service in March 1987. The 360300 introduced advanced six blade propellers, more powerful PT6A67R engines giving a higher cruise speed and improved hot and high performance, plus other aerodynamic improvements. The 360300 was also built in 360300F freighter form.

|

|

Other ESSENTIAL Files:

Base aircraft from Premier Aircraft Design

NB. Readme txt comments on mdl files

|

Repaints by Jack Ford

|

|